News

Home / News

Trainee project “Hau-den-Lukas” 2.0

High-tech in a plastic box

Many people are familiar with the phrase from school: the aim is to prepare young professionals for “real life”. A phrase to which the trainers at MK Versuchsanlagen und Laborbedarf e.K. feel particularly committed. The goal of any training at the special plant manufacturer from Mücke is not only to teach the career starters how to handle machines, technology or administrative skills. “We are also concerned with creating an awareness of everything that needs to be considered in the development, project planning and implementation, right up to the sale of a product,” says MK owner Michael Keil, explaining his company’s training goals.

The apprentice project is relaunched every year

This is put into practice every year in the newly launched “MK Trainee Project”. Together with their trainers, the trainees from all departments of the company are involved in the implementation. And at MK Versuchsanlagen, there are quite a few:

- Technical:r product designer:in, field of mechanical and plant engineering

- Cutting machine operator, specialising in milling technology

- IT specialist, specialising in application development

- IT specialist, specialising in system integration

- Process mechanic, plastics and rubber technology

- Electronics technician, devices and systems (EGS)

- Electronics technician, industrial engineering

- Industrial clerks

The title of the current project was “Hau-den-Lukas”, following the classic fairground model. But since in the plastics processing company, sledgehammers in particular are only used once in a while to maintain the outdoor facilities, the idea was to make creative use of the expertise of the MK departments. “And our trainees have implemented this in an excellent way,” Michael Keil praises the team.

Sensitivity and acoustics instead of power

Omid Kamali, who is learning to be an electronics technician for devices and systems at MK Versuchsanlagen, explains the idea: “Instead of force, our “Hau-den-Lukas” is based on the components of sensitivity and acoustics. For this purpose, we installed a drum in a plastic box and an acoustic sensor underneath. Depending on how loud or soft the sound is played on the drum, the LED display coupled to the sensor moves up or down. The task now is to play the drum so softly that the LED display comes to a stop in a previously defined area.”

All MK trainees were involved

All departments were involved with their trainees. Omid Kamali, Simon Lerch, Hermann Miller, Richard Kruner, Jonas Peschka, Constantin Keil and Mark Miloszewski were responsible for the electronics. The software for implementing the acoustic signal was written by Mika Hormel, Malte Herzberger, Robin Gröblacher, Aiana Kurmanova and Valentin Gallen. In production, it was process engineer Lukas Hartmann and machinist Sarah Schnell-Kretschmer who first brought all the plastic parts and the LED column to the right size and then welded them together. Luis Lämmer and Fernando Dörr were responsible for recording the working hours and the cost plan for purchasing.

With the support of the training manager Elektro Vitaly Schwarz, the second and third year trainees developed, produced and presented a fascinating project. At the presentation, some former trainees were already no longer present, as they had already completed their training in the past months.

“I am really deeply impressed,” said company owner Michael Keil enthusiastically. “Once again, our apprentices have shown what it means when everything comes from a single source. I’m curious to see how our digital ‘Hau-den-Lukas’ is received at the training fairs.”

Specialist training areas exclusively for the apprentices

IHK Gießen-Friedberg awards training at MK Versuchsanlagen

Training is the best “provisions” for the journey to success! – With these words, the Giessen-Friedberg Chamber of Industry and Commerce once again honoured MK Versuchsanlagen und Laborbedarf e.K. for its special services to vocational training in the region.

And owner Michael Keil would like to take the initiative to ensure that the company always has enough provisions with it on the way to a successful future. “Year after year, we are happy to offer young people the opportunity to be trained at our company in Mücke-Merlau,” says Michael Keil, inviting pupils to apply for an apprenticeship. There is a wide range to choose from, because MK Versuchsanlagen trains

- Technical product designers in the field of mechanical and plant engineering,

- IT specialists for application development,

- IT specialists for system integration,

- process mechanics for plastics and rubber technology,

- Machinists specialising in milling technology,

- Electronics technicians for devices and systems,

- electronics technicians for industrial engineering

- industrial clerks.

Apprenticeship vacancies 2023

Currently, 16 young men and women are learning a trade at the special equipment manufacturer. “It is always wise to look for an apprenticeship at an early stage. The chances of being able to learn your desired profession are then simply better,” reports Lorena Heider, training coordinator at MK Versuchsanlagen. “In 2023, we are making 13 apprenticeship places available, eight of which have already been filled. We can still offer free places for industrial clerks, electronics technicians both for operating technology and for devices and systems, as well as cutting machine operators. Interested parties can find all the information on our website at www.mk-versuchsanlagen.de/jobs-und-karriere/ .”

But we are also looking ahead. The first applications for 2024 have already been received by MK Versuchsanlagen and show that this forward-looking commitment is worthwhile for school leavers. The statement of the Giessen-Friedberg Chamber of Industry and Commerce underlines this: Training always means taking responsibility! Company owner Michael Keil is happy to take on this responsibility and invites young professionals to join him: “We are proud to employ so many people from the region. We pay special attention to quality in our training, because we want to be able to take on every single trainee afterwards. For this purpose, we have set up our own specialised training areas for intensive training in the respective departments since this year. Anyone who would like to follow their career path here in the Vogelsberg is cordially invited to apply to us.”

Quality through training

March 10th , 2022 – The Gießen-Friedberg Chamber of Industry and Commerce has honoured the company from Mücke for its special services in training..

The Gießen-Friedberg Chamber of Industry and Commerce expressly thanks MK Versuchsanlagen und Laborbedarf e.K. for the fact that the company did not shy away from the risk and offered young people training even in the second year of the pandemic. Freely adapted from the quote by Jane Goodall, “If we take the future seriously, then we must stop leaving it to others and become active ourselves”.

A motto that is entirely in the spirit of the owner of the family business MK Versuchsanlagen, Michael Keil, who has long taken up the cause of promoting qualified young people.

MK Versuchsanlagen wins the Gießen-Friedberg Chamber of Industry and Commerce’s Business Award 2020

Innovations from the Vogelsberg

For years now, the Gießen-Friedberg Chamber of Industry and Commerce has been honouring people and companies whose commitment to a strong economic future for the local region with the Enterprise Award. In 2020, MK Versuchsanlagen is one of the companies honoured. “I am very pleased to receive this award, which is above all a recognition of the successful work and creative output of our employees,” said company founder Michael Keil at the award ceremony. For Corona’s sake, the award ceremony was held virtually.

World market leader and meanwhile one of the largest employers in the Vogelsberg region

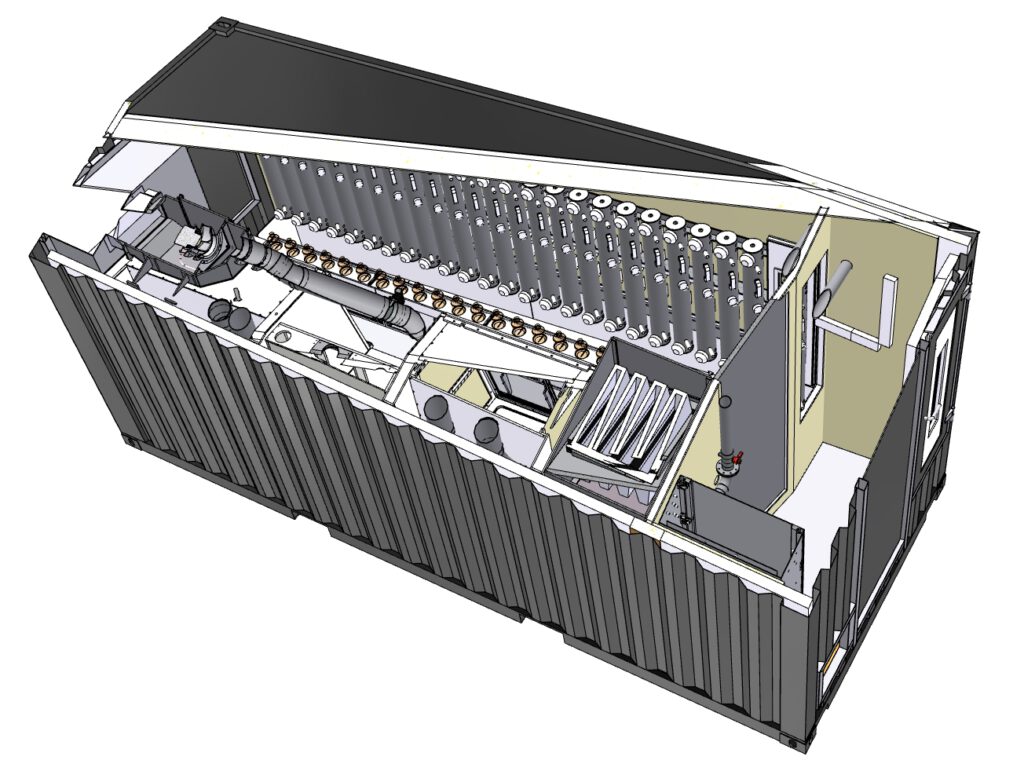

“We are always amazed at what family businesses in our chamber district achieve,” emphasised IHK President Rainer Schwarz in his laudation of MK Versuchsanlagen und Laborbedarf e.K. in Muecke. “Clean rooms from the Vogelsberg, installed in containers, cross the Arctic and Antarctic with the research ship ‘Polarstern’ and ensure the purity of the water samples collected,” he said, explaining the unique selling point of the innovative company. Founded in 1988 as a one-man operation by Michael Keil, the company now has around 160 employees and is one of the largest employers in the Vogelsberg region. The clean rooms developed by MK Versuchsanlagen offer a completely metal-free working environment so that, for example, samples taken in the laboratory are not contaminated.

As a second mainstay, the company has developed glove testing systems for the pharmaceutical industry that make it possible to test 100 or more gloves for damage directly in production in a very short time. Thanks to its own software and electronics development, MK Versuchsanlagen achieves a production depth of up to 95 per cent. So many years of in-house know-how have made the company the world market leader in the glove testing segment. To keep the level of innovation high at all times, the special equipment manufacturer cooperates with the regional universities of Justus Liebig University in Gießen, the Technical University of Central Hesse and the Philipps University in Marburg. The company is currently expanding its site in Muecke. New administrative and production facilities are being built on a further 2,000 square metres.

Representing all the other committed employees, the longest-serving Gertraud Volz, who has been with the company since January 2006, was honoured as a representative. With her calm and even-tempered manner, she has become a pillar of the company and, like numerous other employees from the region, has contributed significantly to the success of MK Versuchsanlagen today.

Curtain up for innovative companies

You can find the presentation of the IHK’s business award at

https://www.giessen-friedberg.ihk.de/

Click here to go directly to the virtual stage of the Giessen City Theatre for the award ceremony:

https://vtc.mediatools.tv/de/vt/rehrzJgjK1/d/148882

Trainee excursion MK Experimental Plants

MK canoeists on the Lahn

The trainees of MK Versuchsanlagen und La-borbedarf e.K. from Mücke-Merlau were on an adventure tour on the river Lahn on 15 September. Trainee coordinator Lorena Heider and trainer Horst Küllmer had organised a canoe trip from Odenhausen / Lahn to Gießen.

It was quite a group of 21 trainees and their two supervisors who went through Merlau in the morning towards the railway station to take the train to Marburg. Already slightly damp from above, they went to the landing stage in Odenhausen. Equipped with life jackets and paddles and instructed on the correct rules of conduct on the water, the eight boats set off down the Lahn. With a white-water feeling, they went over the canoe chute at the weir in Lollar. Otherwise, it was mainly muscle power that was needed to make progress on the calm water.

The teams were on their way for about three and a half hours until they reached the weir in Gießen. After the successful landing, they went to the “Boothaus” restaurant to review their experiences. Everyone agreed: a great day together, with lots of fun for all trainees from all departments.

MK Versuchsanlagen supports young founders

Getting fit for your own start-up

Without bold innovation, even outside large companies, the German economy is likely to have a hard time in the coming decades. Many of today’s internet giants may not have started in the proverbial “garage”, but they did start with an idea and the necessary entrepreneurial spirit to believe in this idea and develop it into a product. This spirit is what the THM’s currently running Ideeco-Summits, which are intended to prepare people to take part in the university’s own start-up competition Ideeco, aim to awaken. “The goal is to prepare people so well that they have a chance of passing the competition at the end,” says Christian Abt from the Friedberg Learning Factory, who organises the Ideeco and the Summits.

MK Versuchsanlagen und Laborbedarf e.K., a company that supports the summits both financially as a sponsor and with technical expertise, is also on board as a partner. More than 60 people interested in setting up a business are currently listening to online lectures, reports on the experiences of other founders and short training sessions. In three blocks of several days, the young innovators are to be given the tools they need to make it to the market and to survive there. In week one, Christian Abt, Anja Shabadi and Prof. Holger Rohn, all from the Department of Industrial Engineering and Management, taught techniques ranging from business plans to the necessary powers of observation and sustainable thinking.

In week two, MK Versuchsanlagen from Mücke was a main partner: the entrepreneur’s daughter and manager Annekathrin Walter spoke about business succession, Christopher Matych as head of finance and human resources presented the essential aspects of his field of activity, and Dr Christopher Keil as head of research and development allowed a glimpse into the life of a product from development to approvals to scaling. Christian Zinke, founder of Keimgrün from Leun, also spoke about e-commerce and sustainability.

The third and final week dealt with the topics of financial planning, funding and establishing a company or start-up story in order to be able to survive a presentation to financiers in a protected space, or at best later in real life. The Sparkasse Oberhessen, also a partner in the Ideeco competition, imparts knowledge and requirements.

28.6.2021 Text: THM / MK Versuchsanlagen

MK Versuchsanlagen develops metal-free laboratory for Polarstern

Highly sensitive research in the Antarctic

Mücke-Merlau, 23 March 2021 / One of the biggest issues in science has always been sample purity. When it comes to protecting valuable finds or samples from contamination, many research groups therefore like to use the metal-free working environments provided by MK Versuchsanlagen und Laborbedarf e.K. from Mücke-Merlau in Central Hesse. This is now also the case for the scientists on board the research vessel Polarstern, which is used to explore the polar oceans and supply the research facilities Koldewey Station in the Arctic and Neumayer Station in the Antarctic. The ship is operated by the Alfred Wegener Institute for Polar and Marine Research (AWI) in Bremerhaven. (…)

MK press release download (german)

Publication Oberhessische Zeitung v. 1. April 2021 (german)

Everyday mask donation for the voluntary fire department

500 everyday masks handed over to the volunteer fire department Muecke

MK Versuchsanlagen has handed over 500 everyday masks to the voluntary fire department Muecke. Dr. Christopher Keil, member of the management, and Annekathrin Walter handed over the cotton masks including mask extensions to the municipal fire inspectors Martin Schlosser and Bernd Wißner.

“We consider the activities of the volunteer fire department to be extremely important in the social network of the community. Such everyday masks are especially important when it comes to the weekly meetings of the junior and new members to practice the handling of the fire extinguishers and to learn routinely. Keeping a distance in the vehicle or during training is largely impossible,” said Dr. Keil, head of the development department, explaining the motivation for the donation.

Bernd Wißner was very pleased about this: “The masks support us in our voluntary work for the Muecker population and show in particular the solidarity with our local companies, which has been growing continuously for years”.

Annekathrin Walter, responsible for quality management at MK Versuchsanlagen, explained the correct handling of the mask extension: “You can wear it in the neck or over the hair, which is a great relief if the everyday mask has to be worn for a longer period of time. The rubber bands of the masks therefore do not rub behind the ears and do not disturb further”.

With this large reservoir of masks it is also possible in the coming months for the voluntary fire department mosquito, especially in the junior sections, to prepare sufficiently for operations.

Quality through training

Excellent training at MK Versuchsanlagen

MK Versuchsanlagen und Laborbedarf e.K. was awarded by the Chamber of Commerce and Industry Gießen-Friedberg for its outstanding work in training its own specialists. “A good training is the beginning” is the motto of the IHK and underlines the great commitment of the company, in which 18 trainees will learn a profession in the training year 2019/2020.

Training young people to become skilled workers has been part of the corporate philosophy at MK Versuchsanlagen for many years. In addition to the classic training professions of industrial clerk, process engineer, cutting machine operator, electronic technician for devices and systems (EGS), electronic technician for operating technology, IT specialist in the field of application development and technical product designer, the company also cooperates at university level and offers dual training in sales and technical development within the scope of various courses of study.

Certificate IHK Gießen-Friedberg

Click here to go to the vacant training positions (german)

MK Versuchanlagen presents wet-dry workbench

Saving costs under perfect conditions

Working under perfect conditions and saving considerable costs is possible with the newly developed metal-free wet-dry workbench, which the special equipment manufacturer MK Versuchsanlagen und Laborbedarf e.K. brings to the market.

The wet-dry workbench, designed as a mini environment, ensures maximum cleanliness on the spot. This is particularly interesting for work processes in semiconductor technology, where the need for the highest levels of cleanliness is only required directly at the workplace (clean room class ISO 3).

Reduction of energy consumption of up to 50 percent in air management is possible

Like all other metal-free systems from MK Versuchsanlagen, the wet-dry workbench is equipped with a ventilation system developed by MK Versuchsanlagen itself, which leads to a significant reduction in energy consumption. The developers assume that energy savings of up to 50 per cent are possible in air conditioning by intelligent air management. Of particular interest is the fact that retrofitting in existing clean rooms is easily possible by means of a special ventilation concept, even in the case of critical room ventilation systems, and thus the energy-saving effect can also be realized here. It goes without saying that the metal-free workbenches also offer maximum corrosion and product protection.

Self-developed hardware and software enables easy integration into existing systems

A Quick Dump Rinse (QDR) basin can be integrated into the wet-dry workbench for cleaning semiconductor plates. The QDR basin has a modular design and is divided into process basins and collecting basins. In the process basin the cleaning of the semiconductor plates or the wafer carrier is carried out. The cleaning is done by a spray system, which fills the basin with high purity water and stops the etching process on the semiconductor wafers. In order to remove the impurities from the semiconductor plates, they are flushed out by the suction created when the valve is opened.

Like all hardware from MK Versuchsanlagen, the software is also a proprietary development of the special equipment manufacturer. This has the great advantage that an integration into existing, superordinate digital systems can be realized much easier. The direct GLT integration is possible as well as the connection to LIMS or MES systems via an OPC UA interface (industry 4.0). Thus it is possible to create an optimal environment that integrates all processes and process devices into the minienvironments.

(Quelle: Reinraum Jahrbuch 2020, S. 156f.)

Download the article as pdf (only in german)

RP Dr. Christoph Ullrich visits top companies in central Hessen

Visit to MK Versuchsanlagen in Muecke – Efficient solutions for cleanrooms

18.9.2019 Giessen/Muecke. “We have many top companies here in Central Hessen that are on the move with innovative ideas – but we have to talk more about them.” Dr. Christoph Ullrich, President of the District Council of Giessen, regularly visits the region to find out how companies not only strengthen the Giessen RP district with its five districts between Limburg and Schlitz, Muenchhausen and Hungen economically, but also make Central Hessen more attractive through their presence. This time he worked for MK Versuchsanlagen in Muecke, which is a leader in solutions for so-called cleanrooms.

The company, which is “a genuine family business”, as owner and managing director Michael Keil explains right at the start of the tour, creates the best quality in modern cleanroom technology with its work and thus guarantees the protection of people and products. In many industries, such as the pharmaceutical industry or food production, work and production under cleanroom conditions are essential. The glove testing system, which is another core business of MK Versuchsanlagen, is also connected to this. In order to work in cleanrooms and to ensure that no impurities can get into them, the company works with attached gloves. With the company’s glove testing system, it is possible to check quickly and accurately whether they are tight.

According to the company owner, the company has been on the market for “30 years” and has developed strongly in terms of topics, space and personnel. It all started with five employees who focused on biotechnological plant construction on a pilot scale for research purposes. The company continues to develop: the product range for pharmaceutical interface solutions is expanded, metalfree cleanroom technology and workstations follow, safety systems and innovations in plant construction are further developed, modern 3D production plants are designed and its own hardware and software are developed.

In the meantime, more than 80 employees work for the company, which Dr. Dirk Rosencrantz from the management describes as a “world product leader”. Owner Michael Keil is certain that they will “continue to grow”. Particularly in the area of glove testing systems, the company is “two years ahead of the other companies and thus attractive for the world market, but also as an employer in the region”.

District president Christoph Ullrich, which uses itself also in its function as chairman of the association central Hessen registered association for the increase of the identity of the region central Hessen, said during the tour: “I do not only surprise today, but again and again, which companies are resident in the region and which for products these manufacture.” Christoph Ullrich was particularly impressed by the glove testing systems.

The district president was accompanied by Andreas Sommer, the mayor of Muecke.

Keyword – association central Hessen registered association and regional management central Hessen GmbH:

The association central Hessen registered association is a partner of the regional management central Hessen GmbH. Under the presidency of district president Dr. Christoph Ullrich bring themselves over 240 members into the regional dialogue, develop ideas and help with the conversion of a centralhessian identity.

The regional management Central Hessen GmbH strengthens and markets the economy and university location in the center of Hessen. The shoulder conclusion from economics, science and politics is active in the topic fields infrastructure, education and specialists as well as research and innovation.

In the regional management Central Hessen GmbH 2013 all chambers of trade, universities, chambers of industry and commerce, districts and upper centers with the association central Hessen put themselves together, in order to develop the regional management existing since 2003 further, and to plan strategies for the region and to convert together.

MK supported ultra-athletes Sven Franke in the charity run for sick children

In July 2016 police officer Sven Franke (2nd from left) started at the 44 kilometre long Zugspitz-Trailrun-Challenge. Under the motto “Running for children” he was concerned about the good cause. In recent years he has collected over 30,000 euros to support the outpatient children and youth hospice service. The coordinators of the aid organization Kevin Leinbach, Dr. Susanne Egbert and Anette Weitzel-Lotz find the commitment of the policeman accordingly outstanding.

Source: www.rg-box.com/?p=12061